OGI technology for superior gas visualization

Real-time methane leak localization

Clear imaging in low-light conditions

High sensitivity, low detection limit

Direct measurement of methane emission rates

Fast and accurate methane quantification

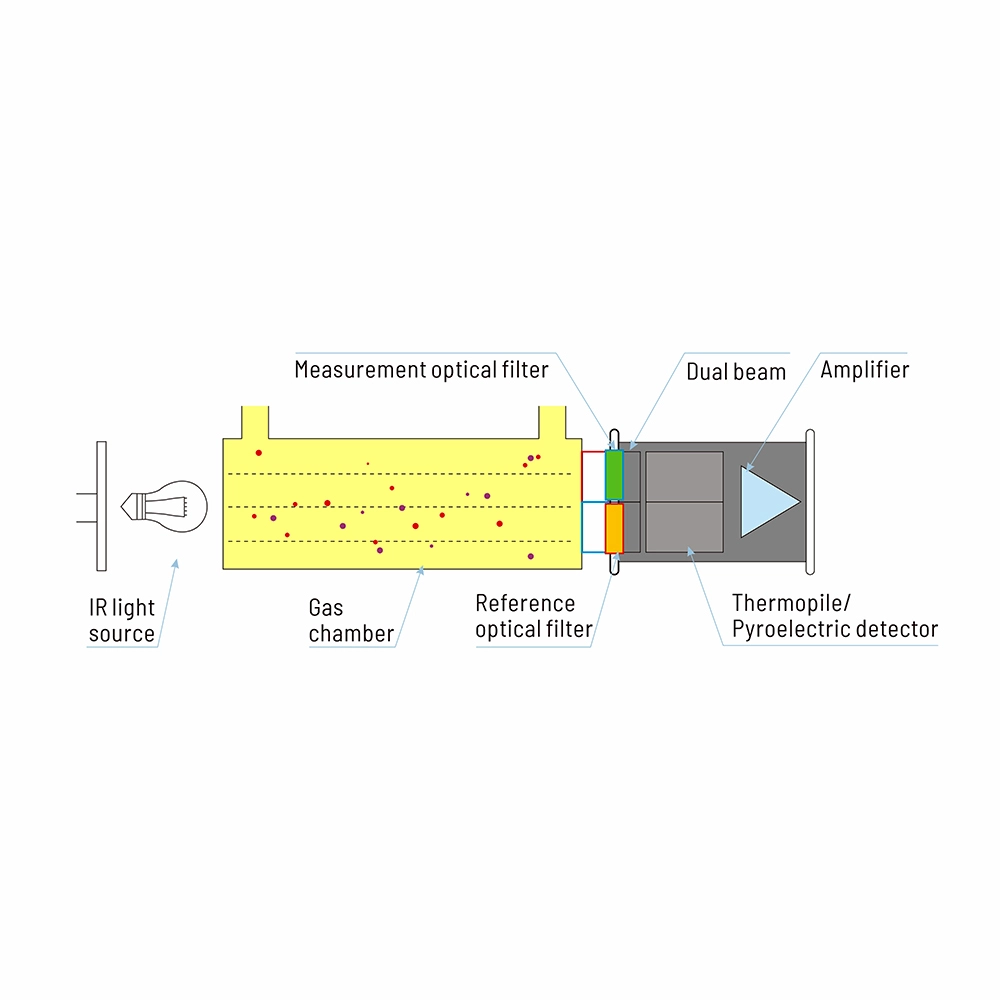

Non-dispersive infrared technology is based on infrared sources. NDIR gas sensors include an infrared emitter, receiver, optical filter, gas chamber, and signal processing circuitry.

The way it works is based on a property of certain gas molecules to absorb light at particular wavelengths. For the purpose of detecting the target gas, infrared light that has been absorbed by the gas travels through the active filter within a certain bandwidth. Using the Beer-Lambert law, the absorption is computed.

With its matrix calibration, Cubic NDIR technology ensures exceptional precision over the entire temperature range. Its dual-beam optical path design and intelligent compensation algorithm also provide dependable long-term stability, resulting in credible safety monitoring.

Compared with electrochemistry, catalytic combustion, solid electrolyte, semiconductor, and photoacoustic methods, the NDIR detection method offers several advantages, including good selectivity, resistance to poisoning and aging from harmful gases, fast response speed, good stability, low cost, and a high signal-to-noise ratio.

Tunable diode laser spectroscopy (TDLAS) is a narrowband laser-based technology. The laser light source, gas chamber, and photodiode comprise the primary components of a TDLAS sensor.

The input current is periodically modulated to align the wavelength with the target gas's absorption optical spectrum. The photodiode will detect the remaining laser light that has been absorbed by the targeted gas. The Beer-Lambert law is employed to determine the absorption. The absorption coefficient of the target gas and the optical path length in the gas chamber determine the extent of absorption.

Cubic TDLAS technology applies a long laser light path through multiple reflections, which facilitates high-resolution quantitive measurement, superior-low detection limit, and low range.

Optical gas imaging (OGI) technology is commonly utilized as a leak detection method in the upstream and midstream sectors of oil and gas industry. The method utilizes a video camera filtered to an absorption band of methane to detect and image methane gas emissions.

The principle of optical gas imaging (OGI) technology derives from visualizing certain molecules in their natural environment by exploiting their absorption characteristics. The focal plane array and optical system of an OGI camera are specifically tuned to a narrow spectral range, allowing only gases that absorb in the infrared region to be detected after passing through narrowband filters.

Contact Cubic Sensor to Explore Innovative Methane Gas Sensing Solutions!

inquiry@gassensor.com.cn

inquiry@gassensor.com.cn

+86-27-81628827

+86-27-81628827

Fenghuang No.3 Road, Fenghuang Industrial Park, Eastlake Hi-tech Development Zone, Wuhan, 430205, China

Fenghuang No.3 Road, Fenghuang Industrial Park, Eastlake Hi-tech Development Zone, Wuhan, 430205, China