Laser Raman technology

Online real time measurement

Wide detection range from 0.1 and 100%

No carrier gas and calibration gas

Shortest response time in seconds

Laser Raman technology

Online real time measurement

Wide detection range from 0.1 and 100%

No carrier gas and calibration gas

Shortest response time in seconds

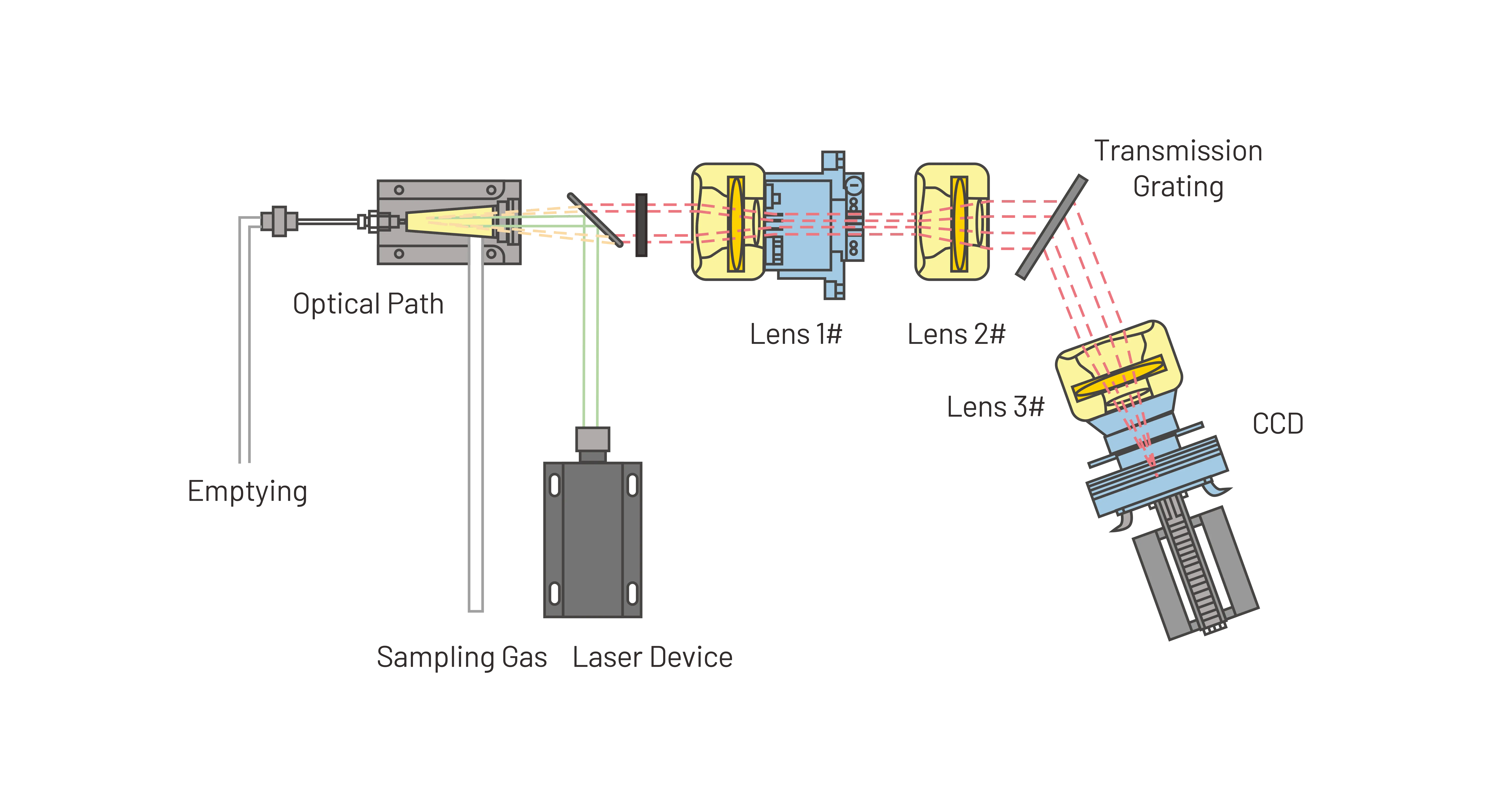

The Raman scattering is an inelastic spectroscopy technique meaning incoming light undergoes a change in color and is scattered with a different energy. The Raman process specifically describes the interaction of incident light with molecular vibrations and rotations in a material. Light can either excite vibrations and lose energy or pick up energy from present vibrations. As the shift in energy is mostly dependent on the material composition and structure and not the wavelength of the excitation light, Raman spectroscopy by Cubic Sensor and Instrument Co.,Ltd. measures the energy shift of the Raman scattered light relative to the incident light energy which is characteristic to the sample that is being measured.

The principle of non-dispersive infrared gas sensing technology is that the gas absorption of characteristic infrared wavelengths conforms to Lambert-Beer's law. The basic principle is that an infrared light source emits an infrared beam through the sampling gas chamber, and each gas component in the sample gas absorbs a specific frequency infrared rays. By the detector to receive and measure the infrared absorption of the corresponding frequency, combined with the algorithm analysis set in the embedded software, the concentration of the gas component can be measured. The reason why this technique is non-dispersive is that the wavelength passing through the sampling gas cell is not pre-filtered.

Different gases have their own different absorption spectra due to differences in their molecular structure, concentration and energy distribution. If the absorption peaks of different gases overlap, the mutual interference between these gases must be dealt with. In addition, in a specific wavelength range, gas detection will also be interfered by moisture. Therefore, the use of non-dispersive infrared technology for gas measurement needs to solve the problems of cross interference between different gases, high and low temperature effects, humidity effects, and component noise effects. This requires the integration of gas path, circuit, optical path design and software algorithm Cooperate.

The electrochemical technology works on the principle of diffusion. The sample gas pass through the gas-permeable membrane on the top of the sensor, an electrochemical reaction occurs when the gas reaches the electrode. This chemical reaction initiates a current between the working and counter electrodes, this current is directly proportional to the concentration of measured gas.

Contact Cubic Sensor to Explore Innovative Methane Gas Sensing Solutions!

inquiry@gassensor.com.cn

inquiry@gassensor.com.cn

+86-27-81628827

+86-27-81628827

Fenghuang No.3 Road, Fenghuang Industrial Park, Eastlake Hi-tech Development Zone, Wuhan, 430205, China

Fenghuang No.3 Road, Fenghuang Industrial Park, Eastlake Hi-tech Development Zone, Wuhan, 430205, China